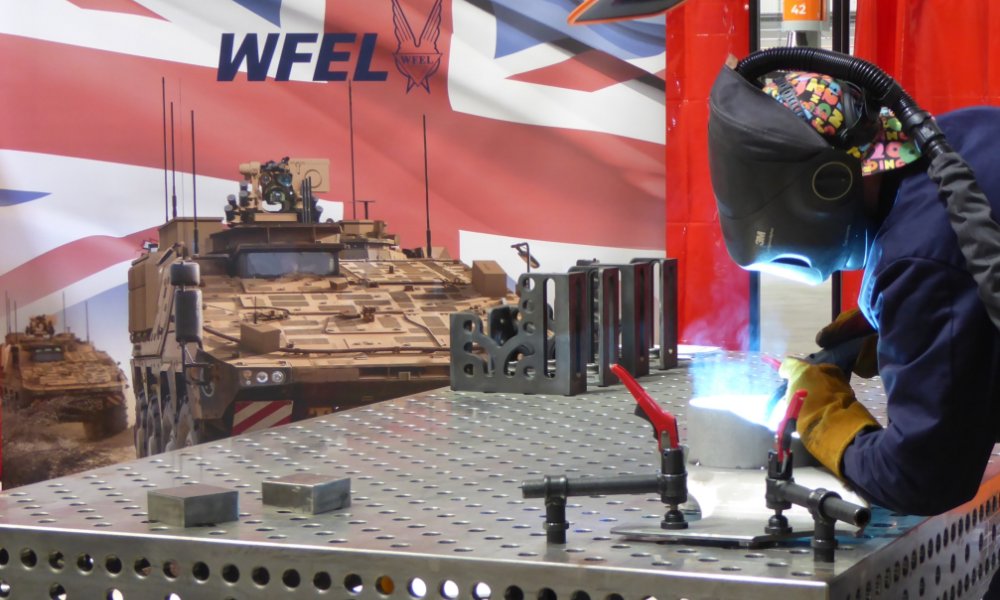

The withdrawal of a second contender to supply both Armoured and Tactical Bridging Systems for the British Army's TYRO project, means that UK military bridge designer and manufacturer WFEL is now the sole bidder. Project TYRO aims to provide UK Heavy Forces with Close Support Bridge (CSB) and General Support Bridge (GSB) capabilities for the British Army's Royal Engineers (RE) to cross wet and dry gaps, both on the battlefield and in emergency and disaster relief situations.

The TYRO requirements are for Close Support Bridges (CSB) to be deployed, launched and recovered from armoured vehicles (AVLB) and a wheeled launcher (WVLB) and for the General Support Bridges (GSB) to be self-deployed, providing MLC 100 (Tracked) capability in order to support unrestricted crossing by UK Heavy Forces.

The Assessment Phase (AP) of Project TYRO has already been successfully completed by WFEL, with the Invitation to Negotiate (ITN) being issued in September 2020. Negotiations for the Demonstration & Manufacture phase will now commence in the summer of 2021.

The bridging solutions offered by WFEL include the DSB Dry Support Bridge - which can be fully deployed by only eight people and a single launch vehicle in under 90 minutes - for the GSB requirement; to meet the CSB requirement, WFEL offers KMW’s LEGUAN Bridge. The LEGUAN's fully automatic, horizontal bridge-laying capability provides increased stealth with a low silhouette during a five-minute bridge launch and will be adapted to be launched and recovered from the MoD’s already in-service TITAN armoured bridge launchers and a new wheeled bridge launcher.

The TYRO Assessment Phase saw WFEL carrying out comprehensive stress and fatigue testing, to verify MLC ratings and life expectancy of the different bridge types and also allowing WFEL to incorporate future Bridge Fatigue Management Systems.

WFEL and KMW extensively demonstrated the capabilities of their mobile bridging systems against MoD user requirements, with particular emphasis on the systems’ load carrying capability and overall durability.

WFEL's Dry Support Bridge is one of the world’s most technically advanced, rapidly deployable military bridges of its type. Over 150 systems have already been supplied to the US, Australian, Swiss and Turkish armed forces. Having also been used as temporary infrastructure in Iraq and Afghanistan, the bridge has been designed and proven for use in both Military and Disaster Relief situations by loads of up to 120 tonnes. This significant installed base of equipment ensures that WFEL's DSB customers have a high level of confidence in continued through-life support and spares availability.

The DSB launch vehicle is available on the user’s choice of chassis and its adoption by the Australian Defence Force onto Rheinmetall MAN Military Vehicles (RMMV) 10 x 10 fully armoured chassis, has further strengthened the DSB’s market dominance, enhancing the system’s compatibility with UK MOD’s current fleet of RMMV vehicles, including HX77 variant, which is already capable of carrying WFEL’s bridge system without modification.

A key requirement for military equipment is interoperability; WFEL's precision engineering manufacturing techniques ensure that any DSB bridge module is compatible with any other DSB bridge module, independent of the chassis used for the bridge launcher, allowing swapping and sharing of resources during NATO and other joint exercises worldwide.

Already selected by 19 armed forces, KMW's LEGUAN bridge system is outstanding in terms of modularity, interoperability and load-carrying capacity and is well suited to meet the UK’s CSB requirement. Beyond its core ability to launch a bridge under any condition within minutes, the LEGUAN system provides additional features to enhance its tactical value, including night vision systems, laser range finder, auxiliary power unit and crew compartment cooling system. The LEGUAN can be used in Military or Disaster Relief operations and, for both MLC80 and MLC100 bridge types at either 26m or 14m length, a life cycle monitor system, and a civilian-use kit - consisting of centre cover plates and handrails - is available. To date, KMW has supplied almost 250 tracked LEGUAN systems, 45 wheeled LEGUAN systems and almost 500 bridges plus 5 ferry and floating kits to some 19 users, with many of these being NATO members.